We make your metalgraphic process more efficient and profitable!

WHO WE ARE

In 2002, a group of professionals with solid experience in the Metal-decorating process decided to create a company focused on meeting the needs of Metal-decorators, offering technical solutions (products and services) for continuous improvement of offset printing processes in metal sheets.

TIMELINE

In 2002 Metalitho was created for the purpose of attending the Metal-decorating market with excellence in specialized training services and technical (advising) advice on demand.

Since 2003, Metalitho has been the only representative of Crabtree of Gateshead in Brazil, adopting 9 other countries of South America during this time period. Also, since 2005, Metalitho has assumed the technical representational aspects of the German company Phoenix Xtra Blankets (Continental Group), offering support in Metal-decorating specifications and training on best practices for the use of high performance blankets.

Through our consulting services, we have implemented Lean Manufacturing techniques - Lean Manufacturing - 5S's, standardization of processes, control of key variables, definition and monitoring of KPI's, Efficient Setup (SMED), among others management tools.

As a consequence of the specialized technical consulting services in Metalgraphy, Metalitho has been the company responsible for the largest number of supplies, upgrades and installations in metallurgical printing and varnishing equipment in South America.

WHAT WE OFFER

We have an excellent portfolio of possibilities in providing services. Our strategy has always been to approach our customers to understand their needs and offer customized solutions for each demand.

CONSULTING

We offer technical consultancies for improvements in the performance of Metalgraphic processes, we rely on the training and qualification of the teams in order to excell results, improving quality and increasing productivity and profitability.

EXCLUSIVE TECHNICAL REPRESENTATIVE PHOENIX

We are responsible for specifying Metalgraphic blankets of Phoenix Xtra Blankets in each application for our customers. We take care of monitoring all homologation tests, we also give workshops highlighting good practices. demanded to the printers in the proper use of this important input, aiming at its maximum useful life and the best relation Cost Benefit to Metalgraphic.

MANAGEMENT OF COLORS &DIGITAL TESTS

With in-depth color management expertise for metallurgical processes, we advise our customers in all stages of the process from prepress with digital proofs that accurately and consistently reproduce the results of offset printers.

SOME OF THE PROJECTS CARRIED OUT

Among the several projects already developed, we can highlight the following:

CERVIFLAN

Supply of various Metalgraphic equipment with UV & Conventional technology.

CMP

Supply of metalgraphic equipment and upgrades.

Consulting and various training in the prepress and print sectors.

CINBAL

Supply of various Metalgraphic equipment with UV & Conventional technology.

Consulting and various training in the prepress and print sectors.

AMBEV - AROSUCO

Supply of metalgraphic equipment and upgrades.

Consulting and various training in the prepress and print sectors.

OUR CLIENTS

Supply of metalgraphic equipment and upgrades. Consulting and various training in the prepress and print sectors.

WHAT THE METHODOLOGY METALITHO CAN DO FOR YOUR COMPANY ...

Contact us for a diagnosis of your Metalgraphic sector.

IMPROVE THE EFFICIENCY OF EXISTING STRUCTURE.

Use of key indicators to measure and control your process.

IMPROVING EQUIPMENT AND PROCESSES

Access to upgrades and new printing technologies to meet your demands.

BECOMING MORE COMPETITIVE THROUGH TIP TECHNOLOGY!

Combining state-of-the-art technology with the best management practices will make your company more competitive.

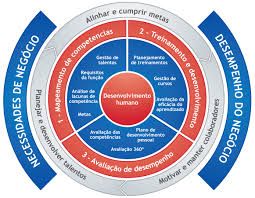

OUR METHODOLOGY - MM

The Metalitho Method of work was developed from the experience of those who have more than 20 years of experience in the metalgraphic market and is composed of 3 fundamental elements:

Diagnosis

ASSESSMENTIdentify opportunities for improvement in the existing structure

In this first step, we work to know the profile and identify opportunities for improvement in each client. The focus is to carry out a technical visit at Metalgráfica to diagnose the areas of prepress, maintenance, printing, evaluation of controlled KPIs and the management model adopted.

Focus on Process and Quality

CONSULTING PROJECTDevelop an on-demand consulting project for the client

In this phase, we advise the customer aligning VOP with VOC through tools of Lean Manufacturing - Lean Manufacturing,

Focus on People

MANAGEMENT OF PEOPLEPerformance Management - Competence 360

Through evaluations of competence and performance of metalgraphic operational teams at their various levels of performance, we seek to form High Performance People.

CONTACT

ADDRESS

Street Antonio Poli, 223 Jd. São Vicente - Itupeva - SP 13.295-000 - Brazil

PHONES

+55 11 4496-9296

+55 11 95413-0359

© Copyright 2017 All Rights Reserved Metalitho

WHO WE ARE

PROFILE OF CONSULTANTS